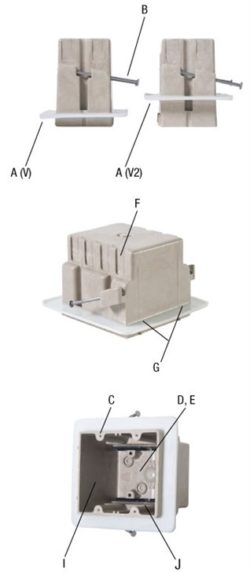

(A) Patented (U.S. Patent #6,908,003 B2) flexible polyurethane flange available for sealing box to air/vapor barrier. Flange products “V” are for single drywall and “V2” are for double drywall applications

(A) Patented (U.S. Patent #6,908,003 B2) flexible polyurethane flange available for sealing box to air/vapor barrier. Flange products “V” are for single drywall and “V2” are for double drywall applications

(B) Bright common nails fit securely in specially designed supports and are angled for easy installation

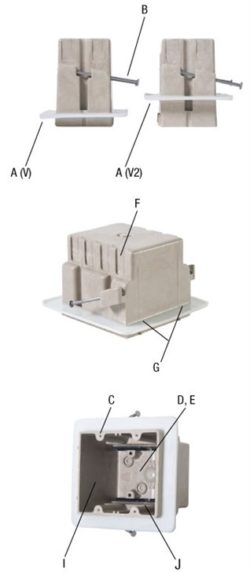

(C) Tapered and machine tapped device holes allow device screw to be started by hand and speed installation time with high torque screwdrivers

(D) Cubic inch capacity clearly marked and easy for contractor and inspector to locate and identify

(E) Proudly UL® listed

(F) Knockouts on fiberglass boxes are complete, reducing drafts and easily removed with wire for no-tool installation

(G) Leveling ribs position face of box parallel to wall surface

(H) 2-Hour Fire Rated clearly marked for easy inspector identification

(I) Nonmetallic Speed “K” Klamps™ dependably secure wire in box

(A) Patented (U.S. Patent #6,908,003 B2) flexible polyurethane flange available for sealing box to air/vapor barrier. Flange products “V” are for single drywall and “V2” are for double drywall applications

(A) Patented (U.S. Patent #6,908,003 B2) flexible polyurethane flange available for sealing box to air/vapor barrier. Flange products “V” are for single drywall and “V2” are for double drywall applications